Medium Voltage Switchgear – What You Need to Know

Medium voltage switchgear (MV switchgear) is a crucial component in electrical power distribution systems. It operates within the voltage range of 1kV to 36kV, acting as a control and protection mechanism for electrical networks. The primary purpose of MV switchgear is to manage and distribute power safely, ensuring system efficiency while preventing electrical faults such as short circuits and overloads.

MV switchgear consists of devices like circuit breakers, disconnectors, and protective relays that safeguard electrical equipment by isolating faulty sections during disturbances. It plays a pivotal role in enhancing electrical system stability and minimizing downtime.

Where It’s Used (Industries, Commercial, Utilities, etc.)

Medium voltage switchgear is widely utilized in industrial, commercial, and utility applications, including:

- Industrial Plants: Manufacturing, mining, steel production, oil & gas refineries.

- Commercial Buildings: Shopping malls, hospitals, data centers, and airports.

- Utilities & Power Distribution: Transmission substations, renewable energy farms, and smart grids.

- Residential Complexes: Large apartment buildings requiring stable power supply.

Role in Power Distribution: MV switchgear ensures efficient and safe power distribution, acting as a mediator between high-voltage transmission systems and low-voltage consumer networks. It provides fault isolation, enabling a seamless electricity flow without affecting the entire grid.

Understanding Medium Voltage Ranges

What Qualifies as Medium Voltage? (1kV – 36kV)

Medium voltage refers to an electrical range between 1kV and 36kV, bridging the gap between low-voltage (below 1kV) and high-voltage (above 36kV) electrical systems. This voltage range is ideal for power distribution in industrial, commercial, and utility applications.

Differences Between Low, Medium, and High Voltage Systems

- Low Voltage (LV): Up to 1kV, used in household appliances and commercial setups.

- Medium Voltage (MV): 1kV to 36kV, utilized for industrial processes, power distribution, and renewable energy integration.

- High Voltage (HV): Above 36kV, essential for long-distance transmission and substations.

Understanding these classifications helps industries select the appropriate voltage category based on their operational needs and safety regulations.

Key Components of Medium Voltage Switchgear

Circuit Breakers: Circuit breakers in MV switchgear are designed to interrupt high fault currents, protecting the network from damage due to electrical failures.

Disconnectors & Isolators: These components enable the safe disconnection of electrical circuits for maintenance or emergency shutdown.

Relays & Protection Systems: Protection relays detect electrical faults and trigger appropriate corrective actions, preventing system failures.

Busbars: Busbars serve as electrical conductors within switchgear, distributing power efficiently among various components.

Switches (Load Break Switch, Earthing Switch): Load break switches allow circuit opening under normal load conditions, while earthing switches provide grounding for safety during maintenance.

Types of Medium Voltage Switchgear

Air Insulated Switchgear (AIS) – Applications & Benefits: AIS uses air as an insulating medium and is cost-effective, easy to maintain, and suitable for industrial and utility applications.

Gas Insulated Switchgear (GIS) – Advantages & Safety Features: GIS utilizes SF6 gas for insulation, offering a compact, high-performance alternative ideal for space-constrained areas.

Hybrid Switchgear – Combining AIS & GIS Technologies: Hybrid switchgear integrates AIS and GIS benefits, optimizing performance and minimizing space requirements.

Metal-Enclosed vs. Metal-Clad Switchgear – Key Differences

Metal-Enclosed: More compact, with components enclosed in a single metallic structure.

Metal-Clad: Provides enhanced safety with individually compartmentalized components.

Working Principle of Medium Voltage Switchgear

How It Operates in Power Distribution: MV switchgear manages and distributes power efficiently, ensuring that faults are detected and isolated without affecting the overall system.

Automatic vs. Manual Operations: Modern MV switchgear can operate automatically via smart relays or manually through operator intervention.

Fault Isolation & Protection: It detects faults such as short circuits and overloads, isolating affected sections to prevent widespread disruptions.

Advantages of Medium Voltage Switchgear

Enhanced Safety Features: MV switchgear incorporates arc-flash protection, fault isolation, and grounding mechanisms to ensure operational safety.

Space-Saving Solutions (Especially GIS): GIS designs are compact and ideal for installations where space is limited.

Energy Efficiency & Reliability: Efficient power management reduces energy losses, enhancing overall system reliability.

Reduced Maintenance Requirements: Advanced switchgear designs minimize maintenance frequency and costs.

Installation & Maintenance Best Practices

Site Selection & Environmental Considerations: Proper site selection ensures safe and reliable switchgear operation, avoiding areas prone to moisture or extreme temperatures.

Routine Inspections & Testing Procedures: Regular testing, including insulation resistance and thermal imaging, helps detect issues before failures occur.

Common Maintenance Issues & Solutions: Issues like overheating, insulation failure, and corrosion can be prevented with proactive maintenance and monitoring.

Safety Measures & Regulations

International Standards (IEC, IEEE, ANSI): MV switchgear must comply with international safety standards, ensuring reliability and compliance with industry regulations.

Protective Measures to Prevent Electrical Failures: Proper grounding, insulation monitoring, and surge protection help mitigate electrical failures.

Importance of Arc-Flash Protection: Arc-flash incidents pose serious risks, making protection mechanisms essential for worker safety.

Medium Voltage Switchgear Trends & Innovations

Digital & Smart Switchgear Technology: Modern MV switchgear integrates IoT for remote monitoring and predictive maintenance.

IoT & Remote Monitoring Capabilities: Smart sensors enable real-time performance monitoring and fault detection.

Eco-Friendly & SF6-Free Solutions: Sustainable switchgear solutions focus on reducing environmental impact by eliminating SF6 gas usage.

Choosing the Right Medium Voltage Switchgear

Factors to Consider (Load, Space, Budget, Safety)

Selecting MV switchgear requires evaluating factors like electrical load capacity, space constraints, budget, and safety requirements.

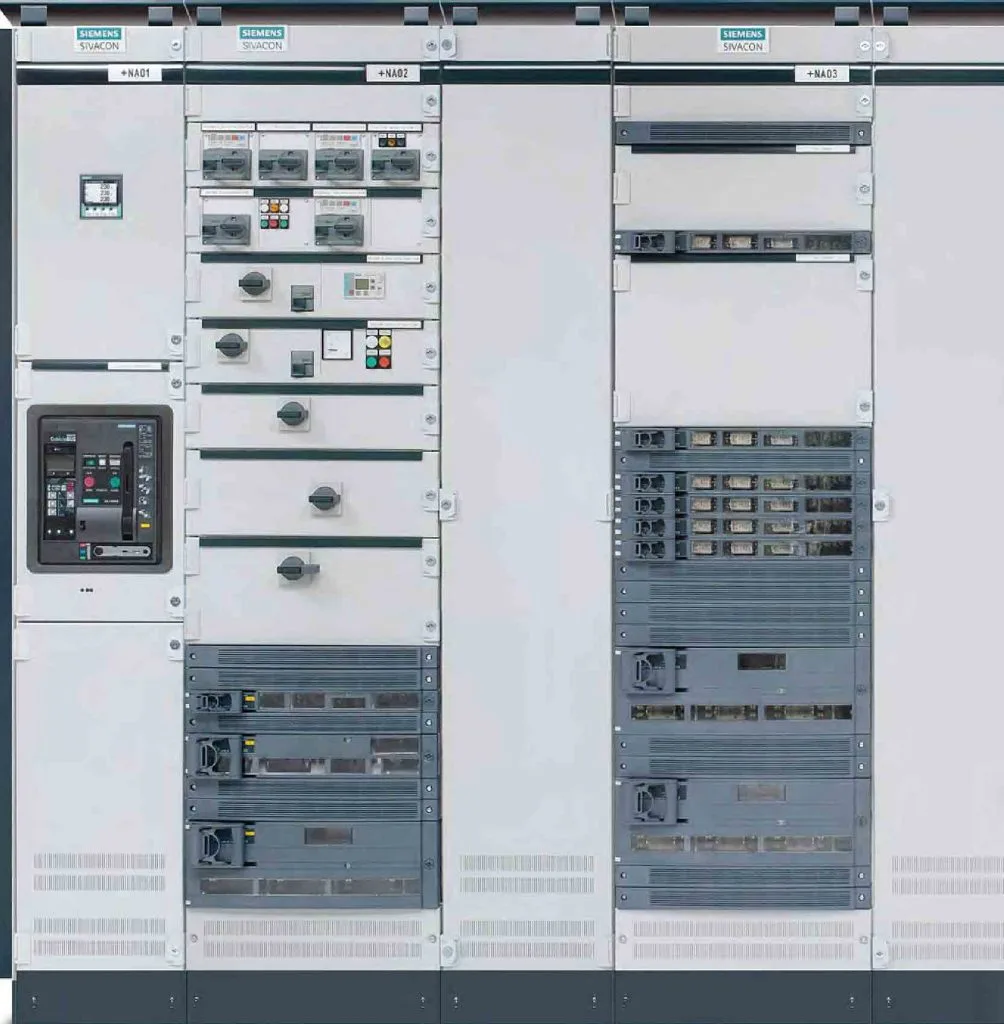

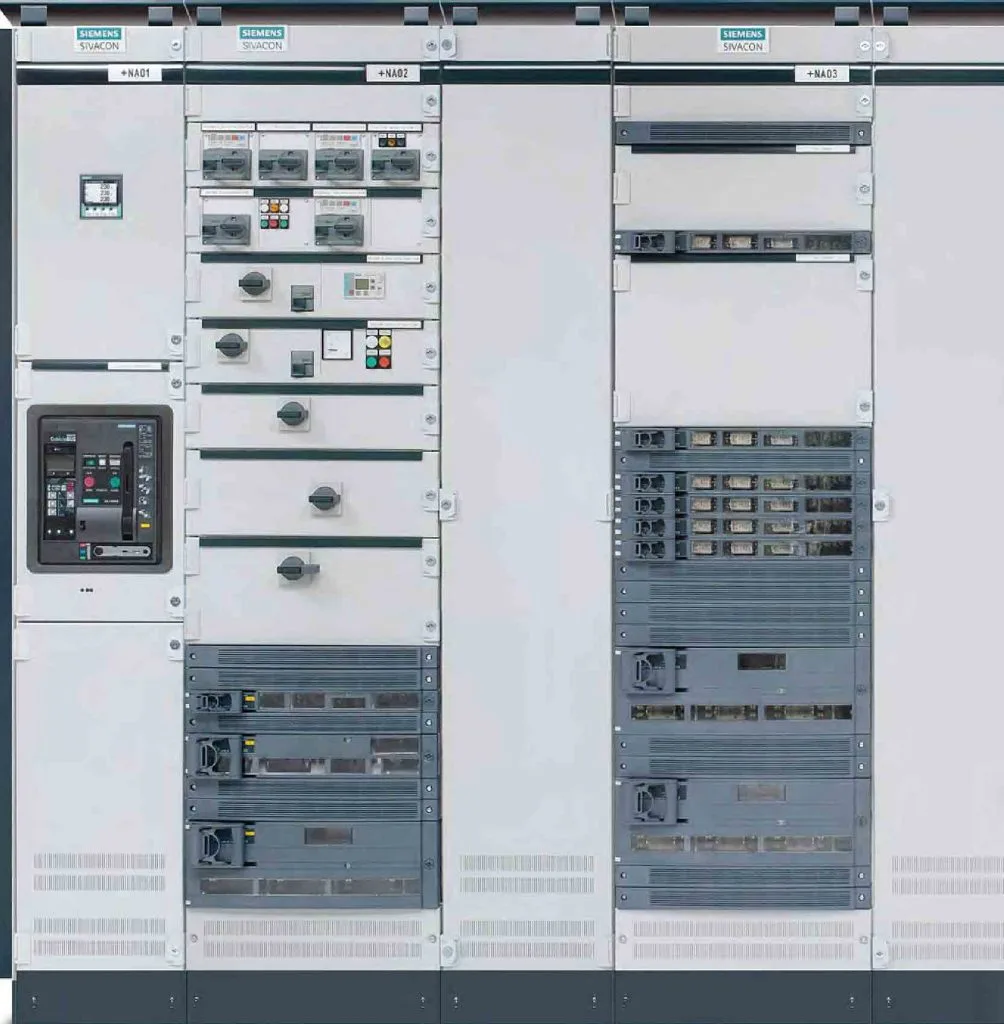

Best Brands & Manufacturers in the Industry: Top global brands include ABB, Siemens, Schneider Electric, and Eaton, offering reliable MV switchgear solutions.

FAQ

Medium Voltage (MV) Switchgear is an essential component in electrical power distribution systems, operating within 1kV to 36kV. It plays a critical role in controlling, protecting, and isolating electrical equipment to ensure a reliable and safe power supply. Industries, commercial buildings, and utility companies rely on MV switchgear to prevent electrical faults, improve energy efficiency, and enhance system stability.

There are several types of MV switchgear, including:

- Air Insulated Switchgear (AIS) – Cost-effective and commonly used in industrial applications.

- Gas Insulated Switchgear (GIS) – Compact, reliable, and ideal for space-constrained environments.

- Hybrid Switchgear – Combines AIS and GIS for optimized performance.

- Metal-Clad vs. Metal-Enclosed Switchgear – Metal-clad offers enhanced safety with compartmentalized components, while metal-enclosed provides cost efficiency.

MV switchgear functions by detecting electrical faults such as short circuits and overloads and then isolating the affected section to prevent system-wide failure. It can operate automatically (via relays and smart sensors) or manually (through circuit breakers and load switches). The switchgear ensures continuous power flow while protecting critical infrastructure from electrical disruptions.

Proper maintenance is crucial for MV switchgear longevity and performance. Best practices include:

- Routine inspections (visual checks, thermal imaging, insulation resistance tests).

- Testing procedures (circuit breaker operation tests, relay calibration).

- Cleaning and lubrication to prevent dust accumulation and corrosion.

- Monitoring for overheating, insulation degradation, or component failures to prevent costly downtime.

MV switchgear must comply with international safety regulations to ensure operational reliability. These include:

- IEC (International Electrotechnical Commission) – Global safety and performance standards.

- IEEE (Institute of Electrical and Electronics Engineers) – Industry-specific safety guidelines.

- ANSI (American National Standards Institute) – U.S. compliance for electrical systems.

- NFPA 70E (National Fire Protection Association) – Arc flash safety and protective measures.

Medium voltage switchgear is integral to modern power distribution, providing safety, efficiency, and reliability. Selecting the right switchgear solution and following proper installation and maintenance practices ensures optimal performance and longevity in any electrical system.